Men Working at Mould, Circa 1919.

Department of the Army. US Army Materiel Command.

Office of the Chief of Ordnance. Watertown Arsenal.

National Archives and Records Administration.

National Archives at Boston; Waltham, Massachusetts.

Early in the 1500s, cannon makers developed casting techniques that made good quality bronze cannon. Some of the innovations to foundry techniques consisted of using vitrified clay molds and casting the guns vertically in pits.

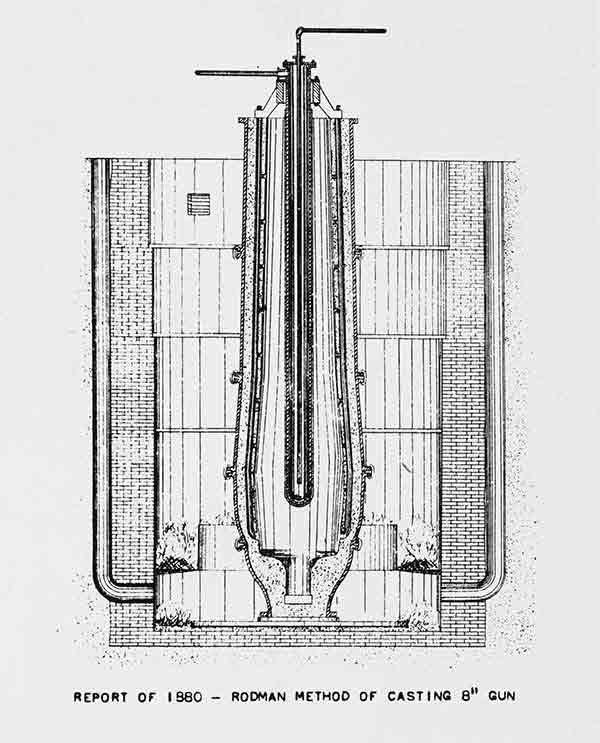

Report of 1880 - Rodman Method of Casting 8-inch Gun.

Department of the Army. US Army Materiel Command.

Office of the Chief of Ordnance. Watertown Arsenal.

National Archives and Records Administration.

National Archives at Boston; Waltham, Massachusetts.

Foundries discovered that casting guns breech down caused the metal to be more dense and stronger near the breech where the stresses are the highest. Cannon were cast with a core that could be removed, thus leaving a hollow casting that could be bored to the desired diameter. Centering the core was difficult and locating fixtures called chaplets were used to hold the core in position. Chaplets were made of wrought iron and the bronze was cast over them. They remained part of the gun.

Casting an Ingot, Circa 1919.

Department of the Army. US Army Materiel Command.

Office of the Chief of Ordnance. Watertown Arsenal.

National Archives and Records Administration.

National Archives at Boston; Waltham, Massachusetts.

In the mid-1700s, machine shop methods advanced to the point that it was possible for advanced shops to cast solid blanks or ingots for guns and bore them out. This resulted in improvements of precision and improved the metal as well because impurities tend to move toward the center of the casting.

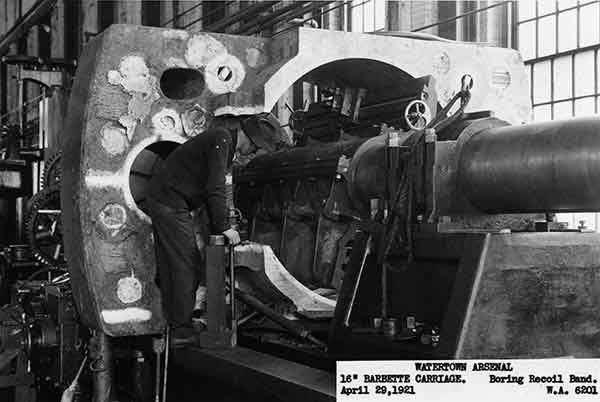

16-inch Barbette Carriage, Boring Recoil Band.

Department of the Army. US Army Materiel Command.

Office of the Chief of Ordnance. Watertown Arsenal.

National Archives and Records Administration.

National Archives at Boston; Waltham, Massachusetts.

The result of all of these developments was that successful bronze cannon were eventually made and they quickly became the best artillery pieces up until about the 18th century in most places. The techniques learned making bronze cannon were useful and carried forward when ferrous metals replaced bronze by about the 19th century.